Description

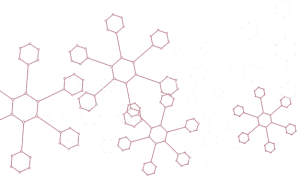

Epoxy Resins are reactive intermediates used to produce a versatile class of thermosetting polymers. They are characterized by the presence of a three-membered cyclic ether group commonly referred to as an epoxy group, 1,2-epoxide, or oxirane.

The most widely used epoxy resins are diglycidyl ethers of bisphenol A derived from bisphenol A and epichlorohydrin. The outstanding performance characteristics of the thermosets derived from bisphenol A epoxies are largely conveyed by the bisphenol A moiety (toughness, rigidity, and elevated temperature performance), the ether linkages (chemical resistance), and the hydroxyl and epoxy groups (adhesive agents). In addition to bisphenol A, other starting materials such as aliphatic glycols and both phenol and o-cresol novolacs are used to produce specialty resins.

The largest single use of epoxy resins is in the protective coatings market where high corrosion resistance and adhesion to substrates are important. Epoxies have gained wide acceptance in protective coatings and in electrical and structural applications because of their exceptional combination of properties such as toughness, adhesion, chemical and thermal resistance, and good electrical properties.

ER E-01 X-75

Applications: Is used for cold cured varnished, solvent based 2-pack coatings for metals, as modifier in stoving enamel based on acrylics, alkyd-melamin resin systems and hot cured adhsives manufacture

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Liquid |

| Epoxy Equivalent | ASTM D1652 | g/eq | 434-555 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.18-0.23 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max.100 |

| Viscosity at 25 °C | ASTM D2983 | Mpas | 6000-12000 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.1 |

| Non-Volatile | DIN EN ISO 3251 | wt% | 74-76 |

ER E-01 X-75 LC

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Liquid |

| Epoxy Equivalent | ASTM D1652 | g/eq | 434-555 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.18-0.23 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max. 40 |

| Viscosity at 25 °C | ASTM D2983 | Mpas | 6000-12000 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.1 |

| Non-Volatile | DIN EN ISO 3251 | wt% | 74-76 |

ER E-05 SPL

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Liquid |

| Epoxy Equivalent | ASTM D1652 | g/eq | 192-204 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.49-0.521 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max.100 |

| Viscosity at 25 °C | ASTM D2983 | Mpas | 15000-20000 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.2 |

| Non-Volatile | DIN EN ISO 3251 | wt% | Min 99 |

ER E-06

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Liquid |

| Epoxy Equivalent | ASTM D1652 | g/eq | 185-196 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.51-0.54 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max. 100 |

| Viscosity at 25 °C | ASTM D2983 | Mpas | <15000 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.2 |

| Non-Volatile | DIN EN ISO 3251 | wt% | Min 99 |

ER E-06 SPL

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Liquid |

| Epoxy Equivalent | ASTM D1652 | g/eq | 185-192 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.52-0.54 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max. 50 |

| Viscosity at 25 °C | ASTM D2983 | Mpas | 10000-14000 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.1 |

| Non-Volatile | DIN EN ISO 3251 | wt% | Min 99.3 |

ER E-10

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Flakes |

| Epoxy Equivalent | ASTM D1652 | g/eq | 588-714 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.14-0.17 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max.100 |

| Softening Point | DIN 52011 | ⁰C | 75-90 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.1 |

ER E-11

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Flakes |

| Epoxy Equivalent | ASTM D1652 | g/eq | 715-870 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.115-0.14 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max.100 |

| Softening Point | DIN 52011 | ⁰C | 84-98 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.1 |

ER E-12

| PARAMETER | TEST METHOD | UNIT | VALUE |

| Appearance | Visual | Visual | Clear Light Yellow Flakes |

| Epoxy Equivalent | ASTM D1652 | g/eq | 800-1000 |

| Epoxy Value | ASTM D1652 | mol/100gr | 0.1-0.125 |

| Color | ASTM D1209 | Pt-Co (APHA) | Max.100 |

| Softening Point | DIN 52011 | ⁰C | 93-105 |

| Hydrolysable Chlorine | ASTM D1726 | wt% | Max. 0.2 |