Description

ETHYLENE GLYCOLS ( EG )

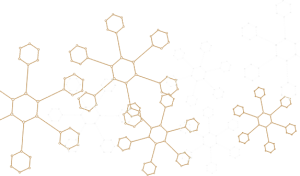

Glycol dehydration is a liquid desiccant system for the removal of water from natural gas and natural gas liquids (NGL). It is the most common and economical means of water removal from these streams. Glycols typically seen in industry include monoethylene glycol (MEG), diethylene glycol (DEG) and triethylene glycol (TEG).

MEG is a colorless, odorless, non-volatile liquid. It is completely miscible in water and many organic solvents. The MEG manufactured is of minimum 99.5 per cent purity and meets the required UV transmittance values specified by polyester manufacturers.

DEG is a stable, high-boiling, odorless and hygroscopic liquid, which is completely miscible in water. It is an organic compound with the formula (HOCH2CH2)2O which is a colorless, practically odorless, poisonous, and hygroscopic liquid with a sweetish taste.

TEG is a colourless, odourless and stable liquid with low viscosity and a high boiling point. It is miscible in water and hygroscopic in nature.

MEG: MONO ETHYLENE GLYCOL

Applications: Latex paints and asphalt emulsions, Electrolytic capacitors, Textile fibers, Paper, Leather, Resins, Deicing fluids, Heat transfer fluids, Automotive antifreeze and coolants, Water-based adhesives

| PARAMETER | VALUE | UNIT |

| Purity | min 99.8 | wt % |

| Color (Pt-Co) | max 5 | – |

| DEG | max 0.08 | wt % |

| Water | max 0.08 | wt % |

| Specific gravity, 20/20°c | 1.1151-1.1156 | – |

| Boiling range at 0.1013 Mpa (5 Vol) | min 196 | °c |

| Boiling range at 0.1013 Mpa (95 Vol) | max 199 | °c |

| Aldehydes (as formaldehyde) | max 8 | mg/kg |

| Acidity (as acetic) | max 10 | mg/kg |

| Iron (as Fe) | max 0.1 | mg/kg |

| Inorganic chlorides (as Ci) | max 0.05 | mg/kg |

| Ash | max 50 | mg/kg |

| UV Transmittance (-220 nm) | min 80 | wt % |

| UV Transmittance (-275 nm) | min 95 | wt % |

| UV Transmittance (-350 nm) | Min 99 | wt % |

DEG: DI ETHYLENE GLYCOL

| PARAMETER | VALUE | UNIT |

| Purity | min 99.8 | wt % |

| Color (Pt-Co) | max 10 | – |

| MEG | max 0.05 | wt % |

| TEG | max 0.05 | wt % |

| Water | max 0.05 | wt % |

| Specific gravity, 20/20°c | 1.1175-1.1195 | – |

| Boiling range at 0.1013 Mpa (5 Vol) | min 243 | °c |

| Boiling range at 0.1013 Mpa (95 Vol) | max 250 | °c |

| Acidity (as acetic) | max 50 | mg/kg |

| Ash | max 50 | mg/kg |

TEG: TRI ETHYLENE GLYCOL

Applications: Polyester Resins, Gas Dehydration and Treating, Chemical Intermediates, Heat, ransfer Fluids, Solvents

| PARAMETER | VALUE | UNIT |

| Purity | min 99.5 | wt % |

| Color (Pt-Co) | max 25 | – |

| DEG | max 0.5 | wt % |

| PEG | max 0.1 | wt % |

| Water | max 0.05 | wt % |

| Specific gravity, 20/20°c | 1.124-1.126 | – |

| Boiling range at 0.1013 Mpa (5 Vol) | min 280 | °c |

| Boiling range at 0.1013 Mpa (95 Vol) | max 295 | °c |

| Ash | max 100 | mg/kg |